-

-

-

Tổng tiền thanh toán:

-

-

Thông tin sản phẩm

-

Tài liệu kỹ thuật

-

-

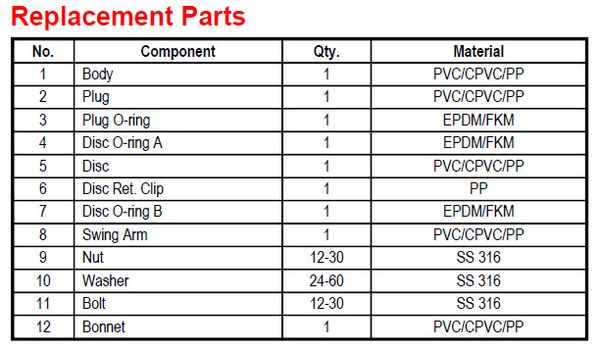

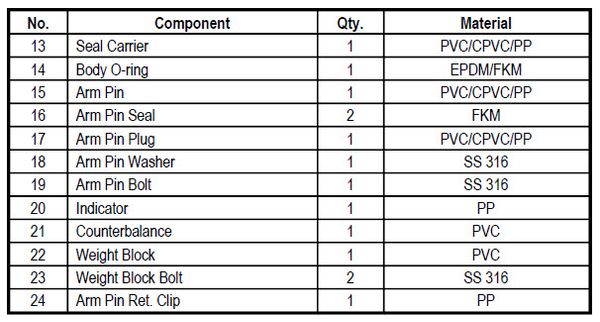

Features — PVC, CPVC & PP

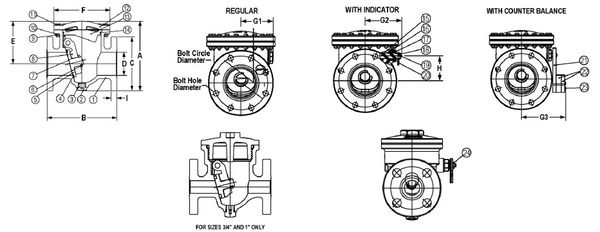

Designed for optimum flow, quick response and positive shutoff with minimum turbulence, this industrial grade Swing Check Valve is used in a variety of industrial and chemical processing applications where high volume fluid transfer is required. Suitable for horizontal or up-flow vertical applications. Available in PVC, CPVC and Glass Filled Polypropylene, IPS 3/4" - 8" with Flanged Body.

• Engineered for Quick Response, Full-Flow Fluid Transfe

• Heavy Bodied All-Plastic Interior Construction

• Top Access & O-ring Sealed Drain Plug for In-line Servicing

• Standard O-ring type Seat & Seals in EPDM or FKM

• Sizes 3/4" - 4" Pressure Rated to 150 psi @ 73°F, 6" Pressure Rated to 100 psi and 8" to 70 psi @ 73°F

• Stainless Steel External Hardware

• Fully Serviceable, Replaceable Components

• Suitable for Vacuum Service

• Assembled with Silicone-Free, Water Soluble Lubricants

Options & Accessories

• External Arrow Position Indicator1

• External Counter Balance1

• Natural Polypropylene Body

1: Available as assembled valve or kit for installed valve

General Installation Information:

Industrial Swing check valves are designed for horizontal installations, but may be installed in up-flow only vertical position. Check valves should be installed a minimum of ten (10) pipe diameters from pump or other sources of turbulence. Check valves MUST be installed with the valves FLOW arrow pointing in the direction of flow. Do not install valve upside down. Normal flange-bolt assembly in top holes of the valve flange requires bolt insertion through the companion flange with nuts secured on Swing Check flange side. Certain system configurations involving direct connection of a Swing Check Valve to other flanged equipment may require consideration of this bolt clearance.

Sample Engineering Specification

All thermoplastic check valves shall be flanged Swing Check type constructed from PVC Type I, ASTM D 1784 Cell Classification 12454 or CPVC Type IV, ASTM D 1784 Cell Classification 23447, or Polypropylene, ASTM D 4101. All O-rings shall be EPDM or FKM. All valves components shall be replaceable. All valves shall have topentry

access with O-ring sealed drain plug for in-line servicing. All valves shall have optional external Arrow Position Indicator or optional external Counter Balance. All 3/4" - 4" valves shall be pressure rated to 150 psi, all 6" valves to 100 psi, and all 8" valves to 70 psi for water at 73°F, as manufactured by Spears® Manufacturing Company.

Địa chỉ liên hệ

Văn phòng Hà Nội

Tầng 2, Green Office - MECO Complex, 102 Trường Chinh, Đống Đa, Hà Nội

0932236260 (Mr.Phong) - 0934 575 626 (Ms.Ly) - 0902372829 (Mr Nhất)

8:00 - 17:00 (Thứ 2 - Thứ 6); 8:00 - 12:00 (Thứ 7)

Kho & Giao nhận tại Hà Nội

Kho F, Trung Tâm dịch vụ cơ điện, Km12 QL1A, Tứ Hiệp, Thanh Trì, Hà Nội

02437921548

8:00 - 17:00 (Thứ 2 - Thứ 6); 8:00 - 12:00 (Thứ 7)

Văn Phòng TP HCM

Tầng 2, Số 137 Đường số 12, Cityland park hills, P.10, Q. Gò Vấp, TP Hồ Chí Minh

0904 579 697 (Mr.Long) - 0936 335 538 (Ms.Loan)

8:00 - 17:00 (Thứ 2 - Thứ 6); 8:00 - 12:00 (Thứ 7)

Kho & Giao nhận tại TP HCM

13D/38N Phạm Văn Sáng, Vĩnh Lộc A, Bình Chánh, TP Hồ Chí Minh

02836200949

8:00 - 17:00 (Thứ 2 - Thứ 6); 8:00 - 12:00 (Thứ 7)

Văn Phòng Đà Nẵng (Miền Trung)